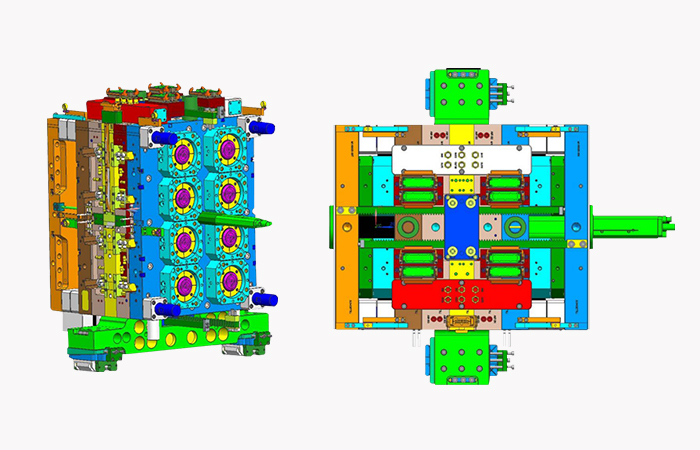

Our experts have more than ten years of experience in mold design, with mindset of product requirements oriented, starting from the DFM report, using Mold Flow, FEA and other tools to do risk assessment, such as filling pressure, molecular orientation, cooling, deformation, sink mark etc., and optimization of gate location and cooling efficiency and so on.

German, Japanese, American and Swiss imported machining and inspection word-class equipment with tight tolerance up to 0.001-0.005mm. Such Yasda, Mikron, Okuma, Makino, DMG CNC; Makino and Agiecharmilles EDM; Kellenberger and Okamoto Grinder; Okuma and Hardinge CNC Lathes; Carl Zeiss CMM etc.

3R automation robot system is equipped with 5-Axis Mikron CNC and Agiecharmilles EDM, could achieve EDM machining and inspection management. Components will be machining in 5-Axis Mikron CNC firstly, then picked up by robot and sent to Agiecharmilles EDM for processing.